Core Shell 3D Molding for higher strength and rigidity

11.03.2024

Toray Engineering Co., Ltd. has presented a 3D Molding Machine for CF Composite Material at “JEC World 2024” in Paris. The machine uses the innovative Core Shell Method.

3D printers used to fabricate 3D objects are known to have “anisotropy” in strength and rigidity as they layer resin and metal materials in the vertical direction, making the mechanical strength and rigidity in the vertical direction inferior to that in the horizontal direction. The Core Shell CF Composite Material 3D Molding Machine Toray Engineering developed reimagines the molding method and uses a light-curing 3D printer to shape the shell, which serves as the mold, little by little while the thermosetting CF composite material is sequentially poured into the mold, and finally the liquid CF composite material is thermoset at once. In this way, the device succeeds in producing moldings without “anisotropy” because, in principle, strength and rigidity are uniform within the molding object, since it is not a layered structure with materials stacked in the vertical direction when it comes to the CF composite material alone. Applying CF composite materials to this molding method enables moldings to be produced with higher strength and rigidity.

Component produced using the innovative core shell method. Photo: Toray Engineering. Photo: Toray Engineering

Component produced using the innovative core shell method. Photo: Toray Engineering. Photo: Toray Engineering

In this component, produced using the core shell method, the shell has been removed. Photo: Toray Engineering

In this component, produced using the core shell method, the shell has been removed. Photo: Toray Engineering

The core material filling mechanism effectively uses the molding space inside the stereolithography 3D printer. The Core Shell CF Composite Material 3D Molding Machine processes epoxy thermosetting resin containing milled carbon fiber (CF) and allows for high-rigidity/high-strength moldings. Possible applications include, for example, various prototype parts, jigs, lightweight and high-strength products, and healthcare products.

A video by Toray Engineering explains how the Core Shell method works: https://tinyurl.com/TRENG-Core-Shell

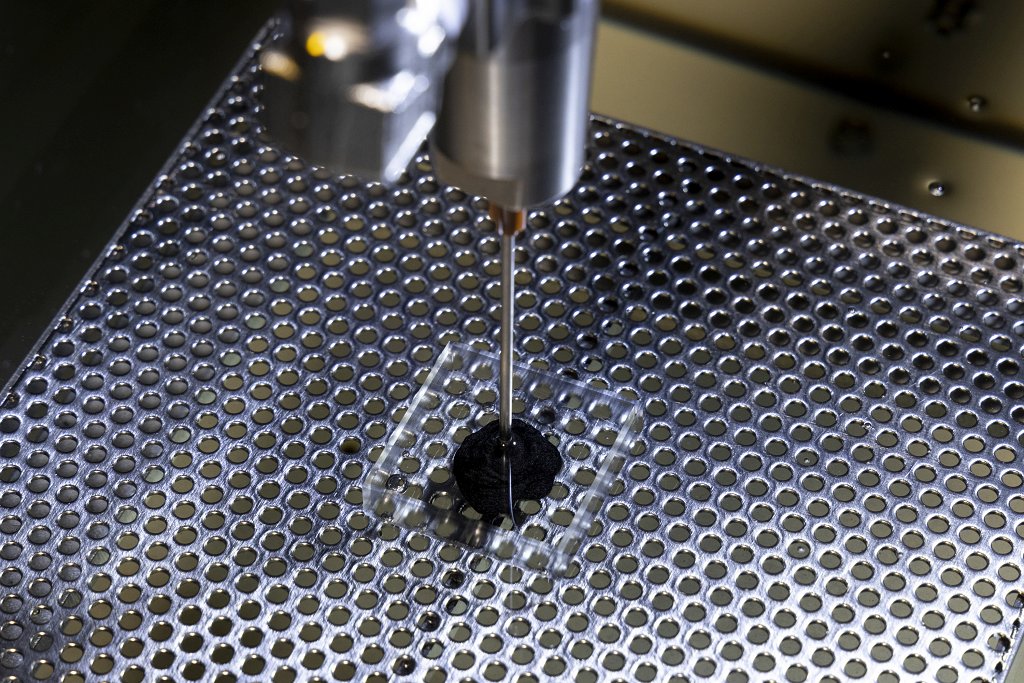

Core Shell method: thermosetting CF composite material is sequentially poured into a stereolithographicly printed mold. Photo: Toray Engineering

Core Shell method: thermosetting CF composite material is sequentially poured into a stereolithographicly printed mold. Photo: Toray Engineering

For more details, please visit: https://www.toray-eng.com.