Outstanding machining competence for mouldmaking

17.08.2020

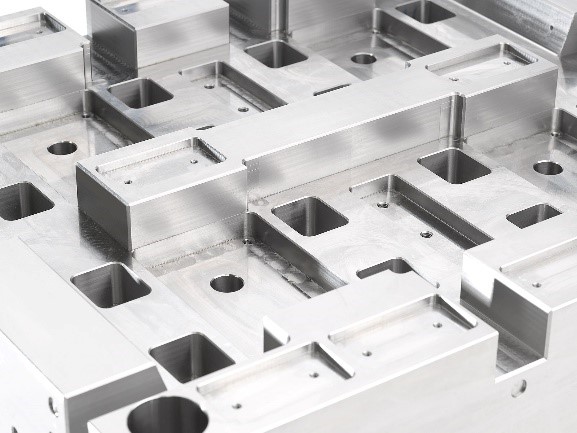

The HASCO Special Machining Center (SMC) supports mouldmakers with all aspects of machining and makes a valuable contribution to achieving greater flexibility and cost efficiency. With machines that are precisely tailored to mouldmaking requirements and excellently trained specialist employees, the SMC constitutes a reliable partner for all the machining operations involved in mouldmaking. Potentially very high cost savings can be achieved over the full length of the value-added chain, from which mouldmakers are guaranteed to benefit. A measurement report can be supplied as an option, confirming the highest level of precision and quality. Punctual delivery is a matter of course.

Just an initial glance at the CAD data is sufficient to show the specialists at the HASCO Special Machining Center what is required. The experts are not only highly trained machinists but also have a great deal of experience in mouldmaking and thus know precisely what to pay attention to. This marks a decisive advantage compared with other special processors. Only someone who understands the subsequent use and function of the parts is in a position to assess whether an edge should be chamfered or not and whether mounting requires a long fit or clearance is suitable. This can only be determined by a machinist who has specialised fully in mouldmaking.

The latest CNC machines and highly trained specialist staff

The machining services offered range from a variety of milling operations and deep-hole drilling right through to grinding. One principle applies to all the processing operations carried out, however – no contour machining is performed. “We adhere very strictly to this principle” stresses Thomas Littringer, Head of the HASCO Special Machining Center, “since this marks the core competence of our customers”. “We aim to support mouldmakers in the best possible way, as an extended workbench”, adds Jörg Scheibenbauer, Head of Production at HASCO SMC, “which is why our machining operations do not include cavities". This then leaves mouldmakers with significantly more time to work intensively on resolving the specific challenges posed by a complex injection mould. An external service provider can also provide profitable support if capacity bottlenecks develop in a company's own mouldmaking shop, such as during a rapid start-up after a plant shutdown.

Complete side machining with deep-hole drilling

The complete side machining of mould plates has become a bestseller in recent times. Employing special deep-hole drilling machines, the SMC drills cooling and temperature-control holes and also holes to a depth of 1,000 mm for cartridge heaters on each side. During the complete side machining of the mould plates, threads for heating/cooling connections can also be cut, recesses made for O-rings and precision mounting surfaces milled for latch locking units, where required. This saves mouldmakers from having to perform the complex side machining with its elaborate clamping operations and allows them to concentrate fully on machining the cavities from above. The large number of customers placing repeat orders confirms the excellent quality and precise adherence to delivery deadlines by the Special Machining Center, a customer benefit that only a company certified to DIN EN ISO can provide over the long term. A measurement report with the specified test dimensions can be supplied as an option, saving the customer from having to conduct an additional incoming inspection of the machined workpieces.

Machining exclusively outside the cavity

The customer benefit derived from outsourcing machining work on mould units is extremely diverse and the savings potential for the companies correspondingly high. In terms of the investment required, some of the highest potential is to be found in the area of machines and tools.

If mouldmaking shops concentrate on machining the cavities, they can adapt their machinery to the new situation. A critical look at productive machine-hours will help here and this also applies to the highly specialised deep-hole drilling machines which are very difficult for small and medium-sized mouldmakers to deploy to optimum capacity. The SMC has invested in these deep-hole drilling machines and doubled its capacity. It can thus achieve very rapid delivery times.

Optimised process chain for shortest delivery times

Of decisive importance for achieving the shortest delivery times in the industry is the process chain, which starts with the customer enquiry and ends with the delivery of the machined workpieces. Over the past few months, the HASCO Special Machining Center has subjected all its sub-processes to a critical review and, together with selected customers, has optimised and, where possible, digitised them. Customers can send their 3D data record or a download link conveniently by e-mail and receive an individual quote within 24 - 48 hours. If a customer decides to place the order, things proceed very quickly, with production commencing once a standardised check of all the necessary data has been completed.

This rapid start to production is possible because HASCO, as a standard-component and hot-runner supplier for mouldmaking, is able to supply the standard steel qualities from stock and thus has very rapid access to a large number of material grades. Employing the latest CNC machines operated by highly trained specialist personnel, all the standard milling processes are offered, from face milling and edge milling right through to machining at an angle. When it comes to grinding too, the customary processing operations are performed rapidly and with maximum precision.

Customised quote in 24 - 28 hours.

Finally, particular attention should be drawn to the highly transparent pricing of these special processing operations for the customer. All the work is calculated on the basis of fixed hourly rates for the machines. These quotes are readily comprehensible for the customer and thus very fair, since capacity utilisation is not included in the pricing at the HASCO Special Machining Center, as is the case for many competitors. This saves customers from unpleasant surprises if a repeat order is placed for a particular plate or if a plate has to be replaced during a repair. Apart from adjustments for inflation, prices remain stable over a very long period. This is a highly decisive factor for a long-term working relationship of equals, conducted on a partner-like basis, which is appreciated by a constantly increasing number of satisfied HASCO customers.

FACTBOX

* Outstanding machining competence for mouldmaking

* Optimised processes for very short delivery times

* Complete side machining with deep-hole drilling

* Individual quote within 24 - 48 hours

* Transparent pricing

Source: www.hasco.com