Streamline your grinding team with DISA GRIND automation

07.01.2025

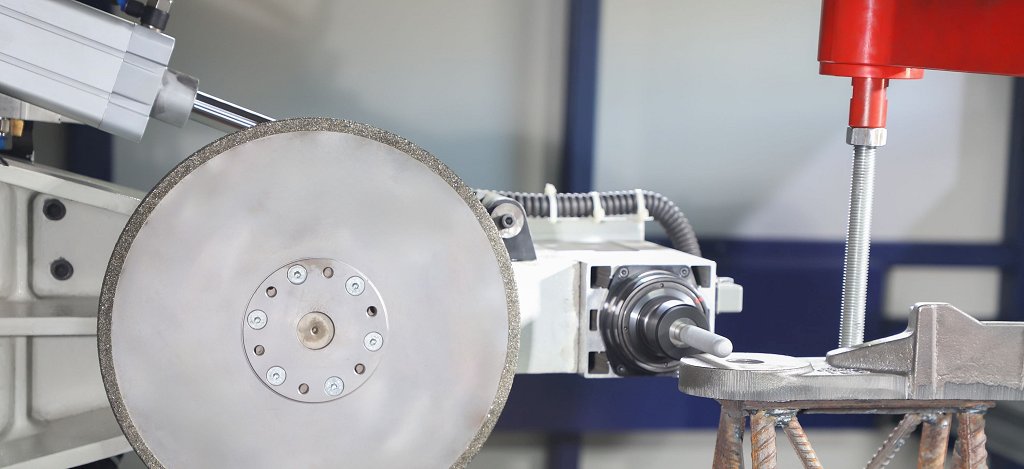

DISA, a Norican technology, has launched DISA GRIND, an automated grinding solution specifically designed for foundries. It can finish all alloys, from iron and aluminum to steel, bronze, and copper.

Fast, flexible and incredibly easy to operate, DISA GRIND is perfect for short and medium runs at small and medium-sized foundries.

“In today’s job market, it is hard to find employees that want to work in manual grinding,” says Kasper Paw Madsen, Vice President Portfolio Development & Marketing at DISA. “Automated grinding with DISA GRIND is cleaner and safer, so it’s much easier to recruit operators and you can train them quickly too. DISA GRIND’s output is accurate, consistent and highly productive, with fixtures that are inexpensive and easy to fabricate.”

DISA GRIND is an automated grinding solution specifically designed for foundries

Easy-to-use auto grinding: productive, consistent and safe

DISA GRIND’s fully automated grinding process is simple to understand. Unlike conventional auto grinding equipment, it does not require CNC programming skills. Anyone can quickly learn to program it using its intuitive touchscreen and handheld control box.

“Adjust the dial to accurately position the grinding tool, then simply press the blue button to record its location,” explains Kasper. “It’s ideal for foundries that handle short runs with frequent new castings. You need far fewer operators, there’s almost no training required, and the work is cleaner and safer, so you can recruit more easily and retain staff longer too.”

Available in two sizes, DISA GRIND can grind castings up to 1200 kg (2,645 lbs). The T-900 handles castings up to 940 mm (37 in) diameter x 400 mm (15.75 in) height and the T-1300 grinds workpieces up to 1340 mm (52.75 in) diameter x 750 mm (29.5 in) height.

"Automated grinding with DISA GRIND is cleaner and safer, so it’s much easier to recruit operators and you can train them quickly too." Kasper Paw Madsen, Vice President Portfolio Development & Marketing at DISA.

Better for your grinding crew, better for your business

DISA GRIND handles small and medium runs equally well, with a pallet-loading option that increases throughput and further cuts labor requirements. Installation is fast too as DISA GRIND requires no special foundation.

Its compact, robust design features auto lubrication and requires very little maintenance, boosting uptime and reducing operating costs. DISA offers online support for quick remote assistance too.

DISA GRIND is ideal for foundries that handle short runs with frequent new castings. It needs far fewer operators, there’s almost no training required, and the work is cleaner and safer

“DISA GRIND is the machine our customers asked us for,” says Bo Wolff Haugbølle, Vice President OEM Sales at DISA. “It is designed and built by foundry experts, and solves a real foundry problem: ensuring consistently high finishing quality while making it easier to recruit and train staff. DISA GRIND is very easy and low cost to run while delivering higher productivity and fast ROI. Now every foundry can have automated grinding that fits their production.”

For more information, visit:

https://www.disagroup.com/GRIND