Reliable and sustainable process for cleaning high-tech components in cleanrooms

18.11.2022

The number of parts which, due to stricter cleanliness specifications, need to be cleaned in a cleanroom is constantly rising - and this is true for many branches of industry. In most cases, these tasks cannot be solved using classic cleaning methods. Thanks to the sustainable quattroClean snow jet technology, however, parts can be cleaned on demand with consistent results in a dry process. The cleaning system, which is adapted to the respective cleanroom class, can be designed as a fully automated system for integration into production lines, or as a stand-alone system for partially- automated or manual operation.

In more and more industrial sectors, particulate cleanliness specifications down to the submicrometer range and exceptionally high filmic cleanliness requirements are making it necessary to shift cleaning processes to a clean or pure environment. These include tasks such as cleaning metallic and optical components - for example, before or after coating - for DUV and EUV lithography in the semiconductor supply industry, as well as structural parts for geostationary satellites in space technology. During microchip production, traces of powder or sawing residues after wafer dicing with lasers or diamond saws have to be removed. When it comes to sensor technology and electronics, it is parts such as optics and housings for assistance systems in vehicles and smartphone cameras that need to be exceptionally clean to ensure their lasting and reliable function. In addition, contact surfaces need to be cleaned before bonding, as well as electronic parts already fitted with components like imagers. In the medical device sector and pharmaceutical industry, the safe use of products such as implants, instruments and lab-on-chip solutions also depends on the cleanliness of the parts. As diverse as these cleaning tasks may be, today’s cleanliness specifications can no longer be reliably met with conventional processes like compressed air, brush or wet-chemical cleaning.

The residual powder formed during wafer dicing with lasers is removed effectively by the quattroClean snow jet technology. Cleanliness was proven using a digital microscope with marks with an external diameter of 0.4 mm.

The residual powder formed during wafer dicing with lasers is removed effectively by the quattroClean snow jet technology. Cleanliness was proven using a digital microscope with marks with an external diameter of 0.4 mm.

Snow for outstanding cleanliness

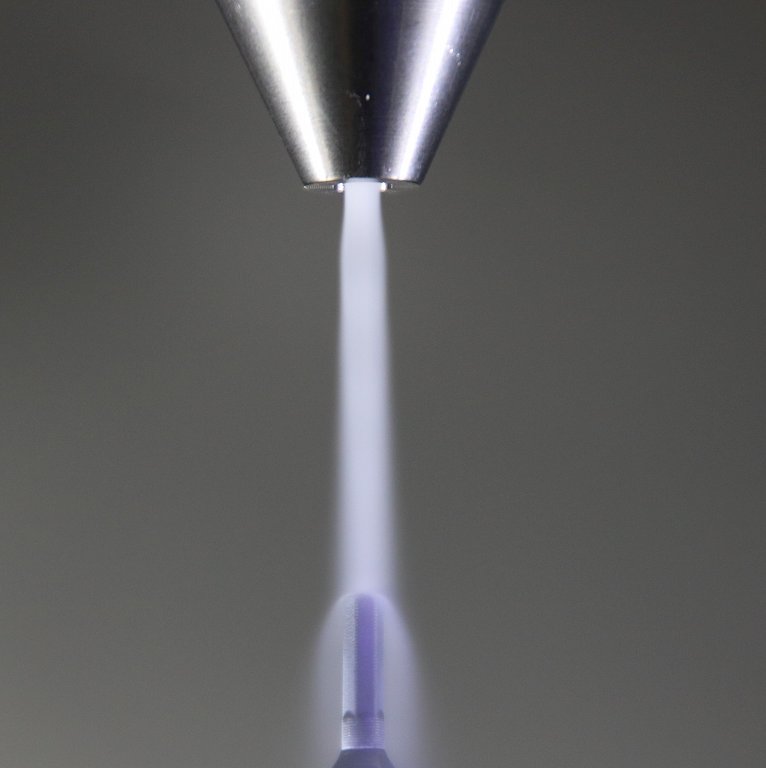

The scalable quattroClean snow jet technology from acp systems AG is a cleanroom-compatible and proven solution for such tasks. The cleaning process is dry and uses liquid, climate-neutral CO2. The key to the reliable cleaning results is the design of the wear-free two-substance ring nozzle through which the carbon dioxide is fed. On exiting the nozzle, the

CO2 expands to form fine snow particles, which are then bundled by a separate jacket jet of compressed air and accelerated to supersonic speed.

The jet is easy to focus on a specific area. On impacting on the surface to be cleaned, the four effects (thermal, mechanical, solvent and sublimation) of the quattroClean snow-jet technology ensure that particles down to the sub-micron range and filmic contaminants are removed effectively and consistently.

Thanks to the interaction of the effects of the quattroClean snow jet technology, particulate contamination down to the submicrometer range as well as the finest filmic contamination is removed reliably and consistently.

Thanks to the interaction of the effects of the quattroClean snow jet technology, particulate contamination down to the submicrometer range as well as the finest filmic contamination is removed reliably and consistently.

Since the crystalline carbon dioxide sublimates completely during cleaning, the surfaces or parts are dry. At the same time, the process is so gentle on materials that it can even be used to clean delicate, sensitive and finely-structured surfaces.

Process design and system design assure excellent cleaning results The process for full-surface or partial cleaning is tailored to requirements through tests in acp systems' technical center. All process parameters, such as the volume flows for compressed air and carbon dioxide, the number of nozzles, the area to be jet-cleaned and the jet time, are precisely tailored to the respective application on taking material properties, the type of contamination and cleanliness specifications into account. These parameters can be filed as part-specific cleaning programs in the system control. During cleaning, end-to-end process monitoring and control guarantee that each part is cleaned using the validated process parameters.

The process itself, where all process parameters are precisely adapted to the respective application, material properties, contamination to be removed and cleanliness specifications, is designed in acp systems' technical center.

The process itself, where all process parameters are precisely adapted to the respective application, material properties, contamination to be removed and cleanliness specifications, is designed in acp systems' technical center.

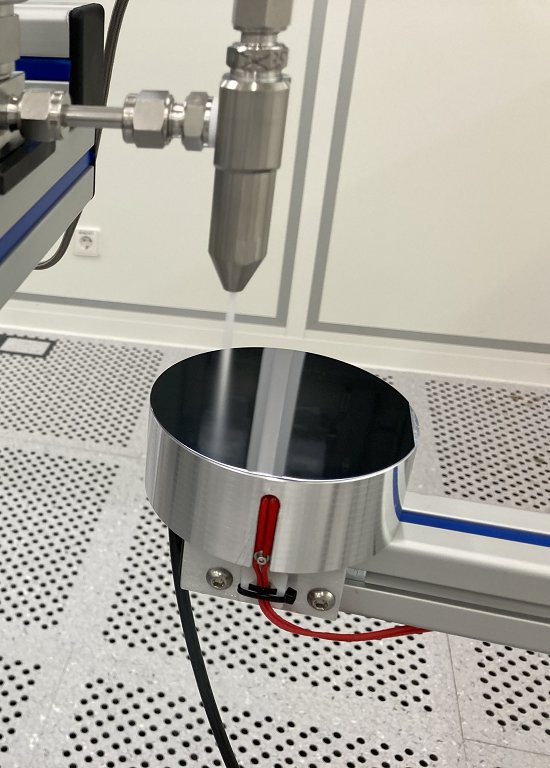

The design and features of the modular cleaning systems are adapted to the respective cleanroom class. Therefore, they are made entirely of stainless steel and have smooth, homogeneous surfaces. The flow-optimized design of the process chamber ensures that the detached impurities and sublimated carbon dioxide are removed rapidly and effectively by the integrated extraction system. Media preparation equipment geared to the task at hand also guarantees that cross-contamination and re-contamination are prevented.

Solutions for integrated, partially-automated and manual cleaning To optimally tailor the cleaning solution to the respective requirements and production situation, acp systems offers various modular solutions and individually planned systems. The compact JetCell-HP was developed for flexible, automated cleaning tasks. The plug & play cleaning cell can be easily integrated into connected manufacturing environments or operated as a standalone solution. The integrated interfaces make it possible to connect the digitally-controllable cleaning system to higher-level host computers.

The JetStation-HP, designed and equipped for cleanroom use, was developed for flexible cleaning tasks with the highest cleanliness requirements. It is loaded manually and can be operated in partially or fully automated mode as a stand-alone solution.

The JetStation-HP, designed and equipped for cleanroom use, was developed for flexible cleaning tasks with the highest cleanliness requirements. It is loaded manually and can be operated in partially or fully automated mode as a stand-alone solution.

All data collected during process monitoring and control can be automatically recorded and transferred to the host computer. The JetStation- HP is a closed cleaning cell for partially-automated or manual operation.

With these cleanroom-compatible alternatives, all the technology for the snow jet process as well as the media preparation equipment are integrated into the system's slender housing. The system is put into operation simply by hooking it up to the carbon dioxide and compressed air supply.

Photos: acp systems

For more information, please visit: www.acp-systems.com