High recycling quality directly from plastic flakes

23.06.2022

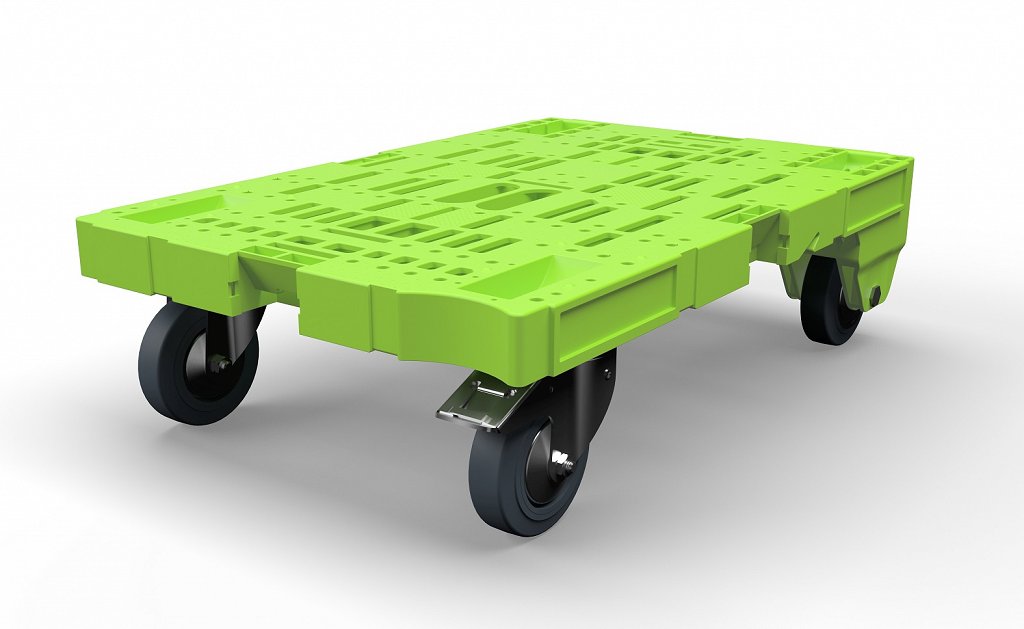

With a new process, ENGEL makes it possible to process plastic waste as flakes in injection moulding directly after grinding. Since pelletising as a separate process step is eliminated, the innovation significantly improves the energy and cost efficiency in plastics recycling. At K2022, ENGEL is presenting the new two-stage process for the first time as a live exhibit at a trade fair. Logistics load carriers with rollers, also known as dolly pallets, are being produced at the ENGEL stand at the Circular Economy Forum in the open air area between halls 11 and 16.

To be able to process flakes in injection moulding, the recycling process breaks plasticising and injection down into two mutually tuned, but independent, process steps. In the first stage, the raw material, for example plastic flakes originating from post-consumer or post-industrial collection, is melted in a conventional plasticising screw. The melt is transferred to a second screw for injection into the cavity. Depending on the material and application, a melt filter and a degassing unit can be integrated into the process between the plasticising and injection units. This means that high-quality products can be created – even from contaminated plastic waste. Processing plastic flakes directly significantly improves the energy and CO2 footprint compared to processing regranulate.

Typically, plastics from post-consumer and post-industrial collection are first ground, and then, after sorting and cleaning, compounded, filtered and pelletised, and finally fed into the injection moulding process as regranulate. This means the plastic has to be melted twice. Pelletising the recycled material is an energy-intensive process which typically also involves logistics overhead. The need for this step is removed completely in the two-stage process. Based on calculations by ENGEL, the energy required for manufacturing the product is reduced by 30 percent.

One focus of the new process is on large-volume moulded parts, many of which, such as pallets, transport boxes and waste containers, are already made from recycled materials today. Integrated degassing extends the usage spectrum to applications in the packaging and automotive industry.

One focus of the new process is on large-volume moulded parts, many of which, such as pallets and other logistics products, are already made from recycled materials today.

One focus of the new process is on large-volume moulded parts, many of which, such as pallets and other logistics products, are already made from recycled materials today.

New degassing unit improves product quality

The ENGEL developers focused on the degassing unit in particular. Degassing is important to achieve high product quality across the board. Residual moisture, and volatile substances originating from material degradation or ink residues, can pass through the melt filter. If these compounds are not removed before the melt is injected, this can lead to pores on the inside and defects on the surface of the part. This not only impairs the visual appeal, but can also reduce the mechanical load bearing capacity of the part.

Another special feature of the ENGEL solution is that the first plasticising unit in the two-stage process also has the task of buffering raw material. This achieves a continuous process which supports the use of smaller screws to ensure further cost savings.

Legacy injection moulding machines as the basis

ENGEL is demonstrating the new two-stage process's ability to perform at the K show in the production of dolly pallets. A blend of polyolefins from a post-industrial collection is being processed on an ENGEL duo 12060H/80Z/900 injection moulding machine.

Production cells for processing recycling flakes in the new two-stage process are based on legacy injection moulding machines. This too also makes a contribution towards lowering the recycling costs and accelerating the establishment of a circular economy for plastics.

The project partners for the presentation at the show are AVK Plastics, which produces pallets on ENGEL duo injection moulding machines in Balk, Netherlands, where some of these machines are already using the new two-stage process, and IPP, headquartered in Ennepetal, Germany, a specialist in logistics solutions for supply chains. The mould for this exhibit comes from Haidlmair (Nußbach, Austria) and the high-performance melt filter for effective removal of solid and elastomer contamination from ETTLINGER (Königsbrunn, Germany). R-Cycle is another partner.

Based on a legacy ENGEL duo injection moulding machine, the production cell for processing plastic flakes has a modular design. The production cell at the K show features a high-performance melt filter by ETTLINGER and a degassing unit.

Based on a legacy ENGEL duo injection moulding machine, the production cell for processing plastic flakes has a modular design. The production cell at the K show features a high-performance melt filter by ETTLINGER and a degassing unit.

Information transparency for value-added recycling

The pallets are equipped with an RFID chip and a QR code integrated by means of in-mould labelling. Visitors to the show can use the QR code to retrieve information on the material and the recycling process from R-Cycle database in real time.

ENGEL joined the R-Cycle Community in the spring of 2022. The objective of this cross-company initiative is to introduce digital product passports for plastics products. All information relevant to recycling is automatically recorded as early as the product manufacturing stage so that, for example, waste sorting plants can identify recyclable plastics more accurately and deliver single grade fractions for recycling. In this way, it is possible to stop the downcycling that has been prevalent thus far and to recycle plastics on a par or even with added value.

ENGEL at K 2022: Circular Economy Forum in the outdoor exhibition area

Photos: Engel

For more information, please visit: www.engelglobal.com