How to save project costs and improve quality with digital twins

15.03.2022

The virtual commissioning of customer-specific machines has the greatest leverage in terms of improving product quality, costs and throughput time. Until now, model creation has been costly and uneconomical due to the lack of mechatronic modular building block systems. Let's take a look at the effects of digital twins for virtual commissioning.

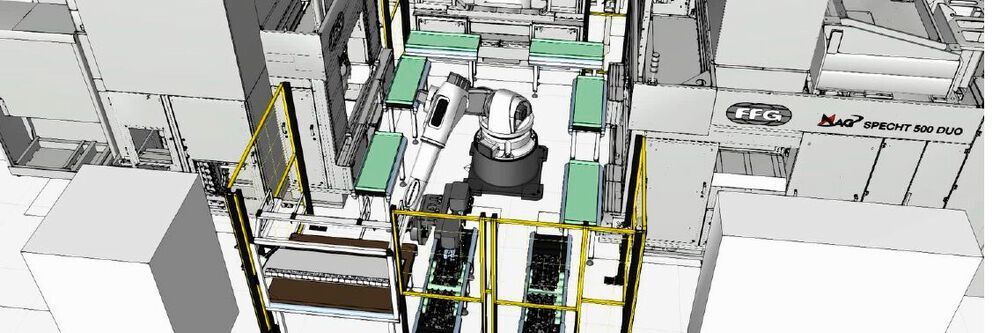

Manufacturing Cell with gantry automation and dual spindle CNC machines 450 Duo installed in the customer plant where both components were merged first time physically but commissioned in different locations in a mixed reality procedure. (Source: MAG)

Manufacturing Cell with gantry automation and dual spindle CNC machines 450 Duo installed in the customer plant where both components were merged first time physically but commissioned in different locations in a mixed reality procedure. (Source: MAG)

For this article, the use of digital twins has been analysed in several assessments with regard to: economic applicability, type of simulation time base, modelling languages or tools and methodology. In the following the efforts and benefits of their use for the project execution of Agile Manufacturing Systems will be shown. The machines for the systems will be assembled from a modular kit and will be equipped according to the given customer specification.

Digital Twins in project execution and delivery

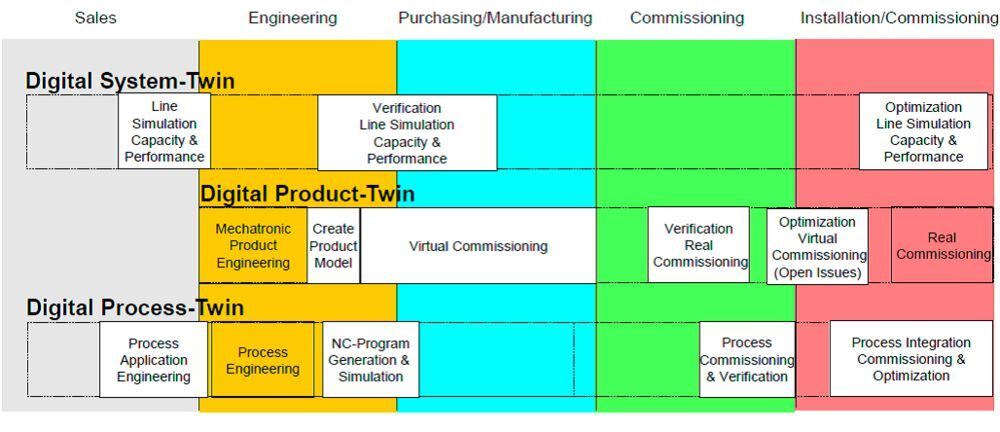

Field of application for the individual Digital Twins during the project execution and their modifications and optimization in relation to the project schedule. (Source: MAG)

Field of application for the individual Digital Twins during the project execution and their modifications and optimization in relation to the project schedule. (Source: MAG)

The field of applications during the project execution, beginning with the sales process up to the start of production (SOP), requires different specifications for such digital models. In the sales process the customer enquiry will be considered regarding the part manufacturing process, the required capacity and the requested layout. The specification will be priced but the models for the proposal process will use the standard modular system of building blocks for the individual machines. The match with the required speed of the application engineering phase the models used for simulation should be rather basic and accurate enough to provide the correct information about cycle time, machine count, correct layout configuration and the overall line performance. With the purchase order and the engineering of the mechatronic design information the Digital Product Twin according to the customer specification will be developed. During the project execution there are different milestones for verification of the simulation as well as the optimization until the final acceptance (FAC) has been achieved. With the finalization of the project all Digital Twins should be updated and will present the virtual copy of the real scope of supply.

There are many digital twins

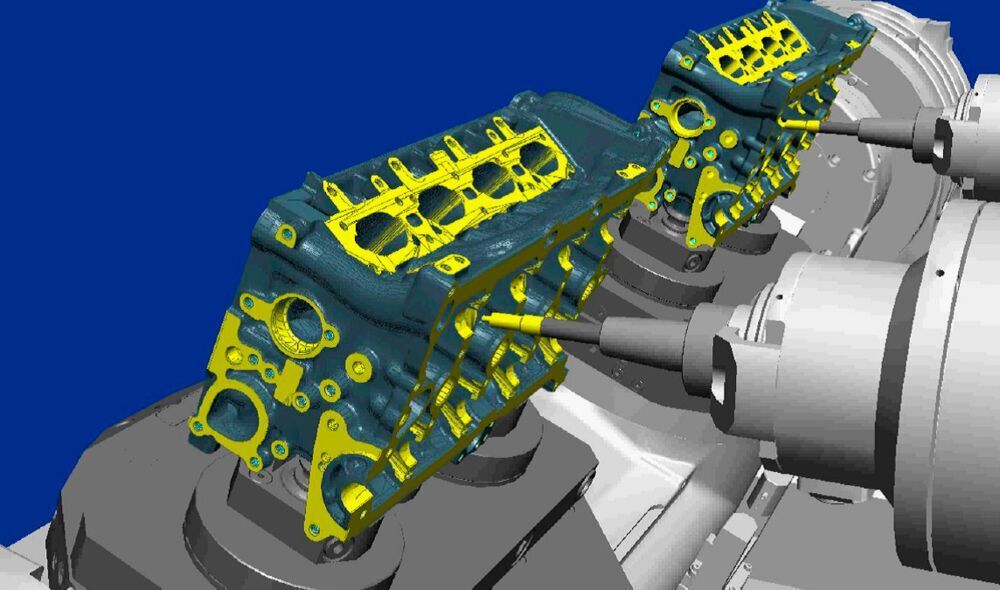

The digital process twin is a work area model and simulates the axis movements, the process-relevant non-productive times, the clamping device, the machining workpiece and the required cutting tools. Compared to a PLC commissioning, the NC commissioning is very short but with clear quality and time advantages.

Digital Process Twin for a cylinder head process on the dual spindled machine Specht 500 DUO with adaptor plates. (Source: MAG)

Digital Process Twin for a cylinder head process on the dual spindled machine Specht 500 DUO with adaptor plates. (Source: MAG)

The Digital Product Twin is a cyber physical model with close to 100 % functionality in combination with an emulated (Software in the Loop or real control (Hardware in the Loop . In addition to the real controller other real products such as valve stacks, actors or interfaces can be connected e.g. via the Ethernet or Profibus/Profinet. In comparison the application based on Hardware in the Loop has been evaluated the best practice solution due to its most accurate copy of the reality. The machine controller (e.g. Siemens 840 Dsl) will be connected directly with the real fieldbus to the PC (e.g. Windows with Twin CAT 3.1) on which the simulation model of the machine is installed. The simulation runs in real time.

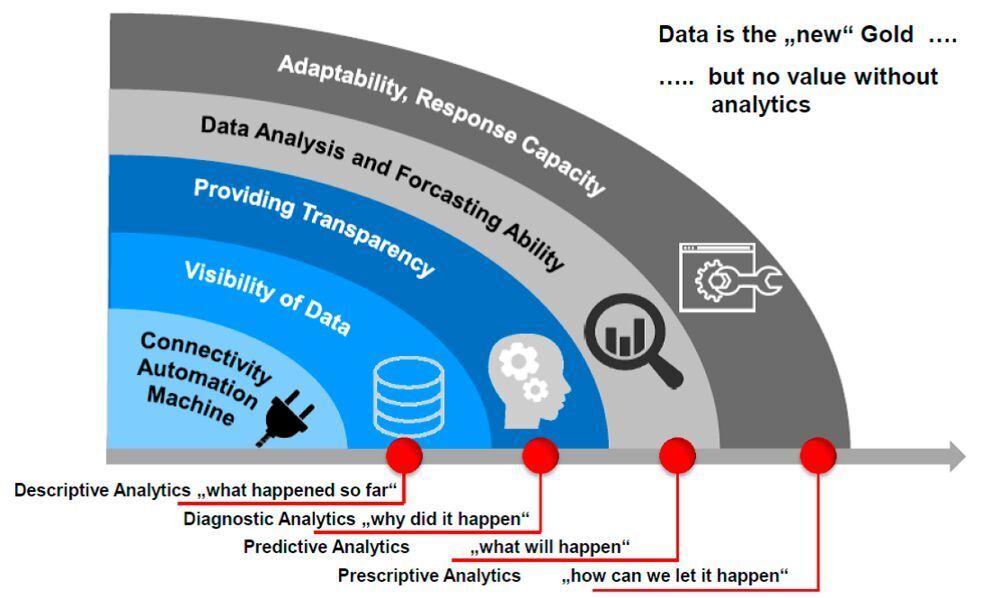

Onion peel model for stepwise intelligent data processing from the production machine for use in new business models. The goal is to achieve “Prescriptive Analytics” for use in OEE optimization of agile manufacturing systems with the simulation on a Digital Twin. (Source: MAG)

Onion peel model for stepwise intelligent data processing from the production machine for use in new business models. The goal is to achieve “Prescriptive Analytics” for use in OEE optimization of agile manufacturing systems with the simulation on a Digital Twin. (Source: MAG)

The Digital Production/System Twin represents the complete installation of a manufacturing/production system as a model. The main purpose of this application is to analyze and optimize the material flow and the calculation of the achievable productivity or OEE (overall equipment efficiency) for the complete system. Both parameters — system throughput and system performance — are contractual obligations and require a simulation model to confirm the specification. With more sensitivity for energy and environment and the investment and operating costs for these topics, simulation models are used to determine power consumption, required connected loads, media consumption (coolant, compressed air, plant water) as well as exhaust air and filter performance.

Virtual Commissioning of Agile Manufacturing Systems

Most of the customers with high volume production issue detailed project specification to take advantage of already trained personnel and existing spare part stock with their inquiries. For the system supplier requires such a specification a quite significant engineering work for their standardized modular machine components as well as for the manufacturing process. For each project an intensive commissioning phase has to be considered to supply the requested quality and meet the safety specifications. To avoid a maximum amount lead time dependent commissioning the development of virtual commissioning and commissioning as a mix of real equipment with virtual equipment offered significant advantages which are most beneficial to supplier as well as to customers. The more accurately a model reflects reality, the higher its quality which is a guideline for Digital Product Twins to be able to simulate reality.

In the future the Digital Twin will become part of the delivery or service and is therefore to be ordered and paid by the customer. This requires a definition of the simulation quality of a Digital Twin, a specification and measures of a validation of such quality.

Creation of the models for Virtual Commissioning (VIBN)

Mechatronic design of components and machines is required to enable efficient model design. The resulting 3D designs of the mechanical machines with the corresponding circuit, flow and pneumatic plans can be read into the software for model creation. The individual assemblies are then assigned the degrees of freedom and the functional parameters (e.g.: maximum travel speed, acceleration and jerk values) in the model. In this way, each element of the machine receives the known functional parameters to simulate the real component. In the first step, the PLC program, which is also provided, is compared with the model and checked for plausibility. The first errors can already be detected and eliminated at this point. If devices are not addressed by the program or if the program addresses devices that are not present, then there are obvious design errors that in the past were not discovered until the real commissioning and were most likely copied in all machines built. Since the model is created during the design phase as an additive activity, the risk of missing recursion, i.e. later changes in the engineering department are being developed in earlier models are not maintained, has to be managed.

Hardware in the Loop (HiL) vs Software in the Loop (SiL)

The virtual commissioning is an anticipation of the PLC program test which is finally performed on the real machine. The aim of commissioning on the model is to shift as much time as possible from the area of the real commissioning relevant to lead time to parallelization with the engineering, procurement and production of the sub-assemblies. With a successful transfer the lead time of a project (for system business approx. twelve months until ex works) can be significantly shortened (manufacturing systems with CNC-machines only approx. four weeks approx. twelve weeks).

Not all functions can be transferred to the virtual commissioning dependent on the customer specification and CE manufacturer’s declaration which does not consider the latest simulation technology. To be able to avoid reruns for the real commissioning the model has to be as accurate as possible to the real machine. To support this request the Hardware in the Loop (HiL) test equipment supplies the best coverage. In addition to testing the functions on the model without any risk of damage, the simulation offers an automatic repetition of functions at the unmanned station. In manual test mode, a function is released after a small number of error-free repetitions. In automatic mode, after delivery, there are singular standstills due to a unplanned stop or crash of the PLC program. Detecting each of these sporadic errors in advance provides noticeable effects in costs (time factor of error correction at the simulator vs manufacturer's plant vs customer's plant: 1:8:40) and software quality. The simulator can be used between delivery and the start of commissioning in the customer's plant to close open issues from pre-acceptance or continue with further program optimization.

The commissioning of the interfaces of an Agile Manufacturing System in reality or mixed reality

The combination of a real robot with a virtual gripper and the representation of the common functional system by means of virtual reality has been state of the art for years and has opened up a new field of application for simulation models. In turn-key plants such as Agile Manufacturing Systems, several suppliers are always involved (Fig. left: Agile Manufacturing Cell with gantry automation and CNC-machines). For commissioning and preliminary acceptance, the two system components built in spatially separate locations had to be physically brought together for the start-up. Unless very conservative end customers insist on this costly and time-consuming procedure, only advantages could be achieved by connecting a real system component to a simulation model (hardware in the loop) via e.g. the Profibus interface. In reality, this was immediately measurable during commissioning after installation in the operator's plant. In addition to the quality improvement of the PLC program, costs and time could be saved by not having to merge the two systems components.

Commissioning of the production management system

Once the installed system in customer’s plant was ready to start production the production system had to be integrated into the customer’s production management computer system. Next to the standard production process also the ramp-up and –down per part type and variant has to be demonstrated to adjust the production management system with the installed new production line. The use of a production-ready production system for a longer period of time (weeks) for integration into a plant production system can now be avoided due to the availability of virtual models and will support an earlier start of production (SOP).

Lead time reduction is a first measurable effect which will be a benchmark against the traditional project execution. Quality improvement is definitely achieved in different areas and will be quantified in a product cost reduction.

From Dr. Manfred Berger, MAG IAS

Source: www.etmm-online.com