Hybrid Production: Supplementing Traditional Manufacturing Techniques with 3D Printing

25.06.2020

Additive manufacturing technology can be leveraged as an intermediate process.

The conversation around 3D printing and traditional manufacturing methods like injection molding or thermoforming is often oppositional, but it’s not always a question of one versus the other. In addition to fabricating end-use products directly, 3D printing offers compelling advantages in hybrid production setups as an intermediate process alongside conventional processes.

By using 3D-printed molds, dies and patterns for various molding and casting processes, you can combine the benefits of these technologies for prototyping and low-volume production. This will make the manufacturing process more time- and cost-efficient and allow for faster production.

This article will describe six traditional manufacturing techniques easily supplemented by stereolithography (SLA) 3D printing: injection molding, thermoforming, casting, overmolding, compression molding and silicone casting.

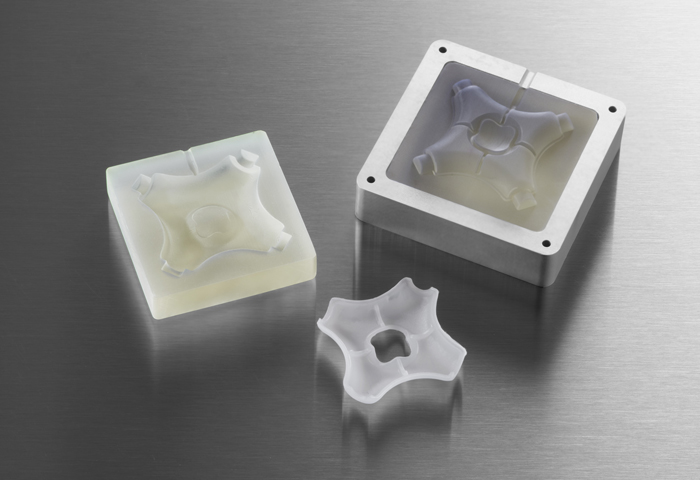

3D-printed injection molds in an aluminum frame with the finished injection molded part.

Injection Molding

With affordable desktop 3D printers, temperature-resistant 3D printing materials and benchtop injection molding machines, it is possible to create 3D-printed injection molds in-house to produce functional prototypes and small, functional parts in production plastics.

For low-volume production (approximately 10 to 100 parts), 3D-printed injection molds save time and money compared to expensive metal molds. They also enable a more agile manufacturing approach, allowing engineers and designers to test mold designs, easily modify them and continue to iterate on their designs much faster, while costing orders of magnitude less than traditional CNC machining.

quip makes products like the quip Electric Toothbrush and Refillable Floss to guide better dental habits.

Thermoforming & Vaccum Forming

3D printing vacuum and thermoform dies is a fast and effective method to create high-quality vacuum-formed parts for small-batch production. Printed thermoform dies can be used to make packaging prototypes, clear orthodontic retainers and food-safe molds for chocolate confections.

Clear aligners for orthodontics are one of the first-use cases of 3D printing for mass production.

Casting

Casting is a popular technique in many industries—jewelry, dentistry and engineering in particular. It can be used for both small and large parts in a wide variety of metals.

In the jewelry industry, for example, 3D printing is part of the investment casting process. Jewelry makers begin by designing a piece digitally and 3D printing it with a castable resin. The piece can then be immersed in a sand-like investment material and cleanly burned away in an oven, just like regular models made of jeweler’s wax, leaving a cast for precious metals.

Castable resin can be used to print a detailed master for casting.

Overmolding

Overmolding is an injection molding process in which one material is molded onto a second material. 3D printing molds for overmolding can be an efficient way to create “looks-like” and “works-like” prototypes (overmolded electronics, for example).

Dame Products, a Brooklyn, N.Y.-based startup that designs products for the health and wellness industry, has a product line that incorporates complex ergonomic geometries, fully encapsulated in a layer of skin-safe silicone in vibrant colors. The team employs silicone overmolding in production to encapsulate internal hardware for customer beta prototypes.

Compression molding

Compression molding is a manufacturing process where materials are compressed into the desired form using two molds. Once again, 3D printing these molds can be time- and cost-efficient for prototyping and low-volume production.

OXO engineers prototyped gaskets by compression molding silicone in 3D-printed molds.

Product developers at OXO, a U.S.-based brand that creates ergonomic and practical items for the home (most prominently kitchen gadget designs), use 3D printing for form and function prototyping, as well as hybrid methods for prototyping rubbery components such as gaskets.

OXO engineers used 3D-printed molds for compression molding when they needed to produce a functional prototype that had watertight seals between parts. They determined that compression molding two-part silicone putty was ideal for creating a watertight prototype that mimics the production gasket. In fact, the prototype compression mold is a good representation of the method and mold design used in gasket manufacturing.

Silicon Casting

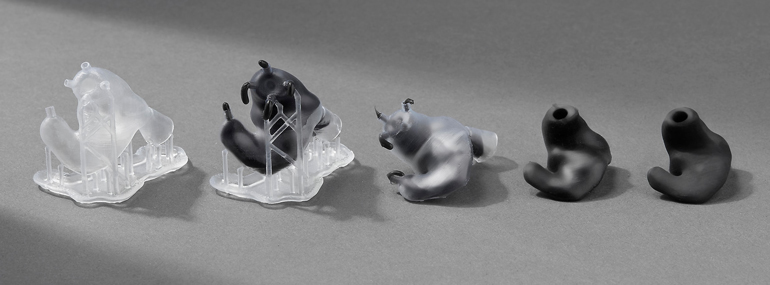

3D-printed shells or molds can also be used for silicone casting, for example, to affordably produce custom silicone earmolds for hearing aids, musician in-ear monitors, high-end earphones and hearing protection.

Custom earbuds are made by casting biocompatible silicone in 3D-printed hollow molds.

Explore step-by-step workflows

The process begins with a fast, non-intrusive digital scan of the customer’s ear canal using a 3D scanner. A technician edits the digital file into a 3D printable mold and sends it wirelessly to an SLA 3D printer. Once printed, the parts are cleaned and the technician casts biocompatible silicone into the molds. Once the 3D-printed shell is removed, the final product is finished and coated.

Hybrid production techniques are expanding the material palette of 3D printing and complementing traditional manufacturing methods. The methods outlined in this article can be used directly, or elements of each borrowed for custom applications.