IRT3000 41/2012

• Days of Mechanical Engineering attract a record number of visitors to the Technical Museum in Bistra

• Celje to host four top international trade fairs in April 2013

• Automation and robotisation in Hella Saturnus Slovenija

• RobotExpert helps improve the efficiency of robots

• Injection moulding and blow moulding in one

• MicroPower – ideal for the moulding of medical small and micro parts

• Interview: dr. Janez Šetina – Measuring pressure with precision

• In the sign of ICT

• 2016 Olympic Games in the »blue« Rio

• FANUC service increases availability and efficiency of machines

• Hand-held Touch Probe

Content

| 5 | EditorialEditorial |

| 35 | Chamber of Craft and Small Business of Slovenia becomes a member of the NAMASTE Centre of Excellence |

| 28 | Celje to host four top international trade fairs in April 2013 Every two years, the specialised international trade fairs Forma tool, Plagkem, Graf&Pack and Foundry bring to one place the most innovative and R&D-oriented companies and individuals. They are the ones who use their knowledge, new technologies and material processing to lay a path to the future. The four fairs will be taking place at the Celje fairgrounds from April 16–19 2013.  |

| 28 | 20 years of ABB Slovenia – history with the future |

| 26 | ACS: Development and globalisation are crucial for the future of automotive industry, Slovenian industry included |

| 22 | 52. International Foundry Conference Portorož 2012 |

| 16 | Bionics for the technology of future |

| 14 | Evaluating the states of acoustic sources |

| 12 | Days of Mechanical Engineering attract a record number of visitors to the Technical Museum in BistraThe Technical museum of Slovenia in Bistra hosted the third Days of Mechanical Engineering in the last week of September. The event aims to present mechanical engineering as well as the purpose and the relevance of studying mechanical engineering in the present time to a wide audience, especially elementary and secondary school youth. The event, organised by the museum staff in cooperation with the laboratories and management of the Faculty of Mechanical Engineering in Ljubljana, has attracted a record number of visitors – more than 2100.  |

Pulse at Home

| |

| 8 | Interview: Hubert Kosler, Yaskawa Slovenija, d.o.o., Ribnica

|

| 40 | 90 years of Hennlich group |

| 44 | Managers propose a work commission

|

Manufacturing and Logistics

| |

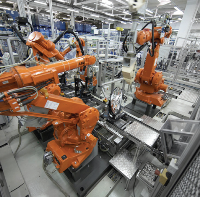

| 48 | Automation and robotisation in Hella Saturnus Slovenija Hella Saturnus Slovenija, a developer and manufacturer of lighting equipment, has been boosting investments into automation for the last ten years, integrating it with other technologies. The result are integrated manufacturing systems, which are not only technically refined, but also economically efficient.  |

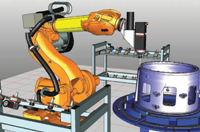

| 52 | RobotExpert helps improve the efficiency of robots Siemens PLM Software has introduced the RobotExpert, a new intuitive and user-friendly solution for robot simulation and programming. It has been developed for small and mid-size companies to cut the non-productive time and improve the productivity of robots in the industry.  |

| 54 | Multi-touch technology, usability and energy management with the new zenon family of tools |

| 60 | How Control Techniques creates new drives of the future |

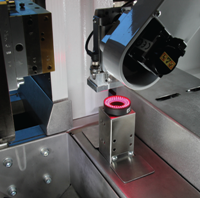

| 64 | New optical sensors from Leuze electronic |

| 64 | IRB 1520 ID welding robot |

| 66 | CompactRIO and LabVIEW Real-Time monitor the condition of switching equipment |

| 70 | XTS – linear motor with a circular path |

| 72 | New ZX measuring sensor series |

| 72 | Fully automated nut insertion

|

| 80 | Small laboratory extruder from KraussMaffei Berstorff for great challenges |

| 79 | EcoPower – the perfect solution for medical technology applications |

| 78 | MicroPower – ideal for the moulding of medical small and micro parts WITTMANN BATTENFELD has responded to the increasing importance of micro parts in medical technology with MicroPower, an injection moulding machine model specially developed for high-precision production of extremely small parts. The all-electric MicroPower – available with clamping forces of 5 and 15 t – is attracting attention from the medical industry due to its speed, its extraordinary cost-efficiency and absolute process reliability.  |

| 75 | ENGEL opens new representative office in Slovenia

|

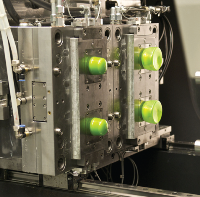

| 74 | Injection moulding and blow moulding in one ENGEL AUSTRIA and CANTONI have set a new standard for process integration. The inject2blow method, which the two companies developed together, combines the injection moulding and blow moulding processes in one mould on one injection moulding machine and significantly reduces time and costs in the manufacture of cosmetic, drug, and food containers by doing so.  |

Non-metals

| |

| 81 | New smaller tempering unit Tool-Temp TT-181 |

| 82 | Indispensable Grivory HT |

| 86 | When standard injection moulding machines support three columns of the house |

| 87 | New WITTMANN W 822 robot for new injection moulding solutions |

| 88 | Fully automated injection moulding of thermoplastic materials

|

Metrology & Quality

| |

| 90 | Interview: dr. Janez Šetina – Measuring pressure with precisionThe Institute of Metals and Technology in Ljubljana boasts with three accredited laboratories – Laboratory of Pressure Metrology, Laboratory of Metallography and Laboratory of Mechanical Testing. The Laboratory of Pressure Metrology, the holder of national reference standard for pressure, is led by dr. Janez Šetina. Vesna Vilčnik  |

| 94 | Measuring pressure |

| 96 | Intelligent measurement of heat meters |

| 96 | Measuring nanoparticles for health protection |

| 97 | The Chamber of Craft and Small Business of Slovenian Award and the 2012 Upper Carniola Gazelle |

| 98 | TQM, continuous improvement, innovation and business excellence |

| 102 | Promoting metrology at 18th Slovenian Science Festival |

| 102 | Potential to save 700 000 tonnes of fertilizer annually through accurate measurements

|

Advanced Technologies

| |

| 104 | In the sign of ICT The last Olympic Games will also be remembered by the most extensive use of information and communication technologies so far, as well by a mass use of digital technologies to distribute the games around the world.  |

| 108 | 2016 Olympic Games in the »blue« Rio It is little known that Rio de Janeiro, a city with six million people that has already started preparing for the next Summer Olympics, will soon be the leading smart city in the world.  |

| 109 | Technology and innovation in the centre of SAP business solution |

| 110 | hyperMILL® 2012 – state-of-the-art and advanced technology |

| 112 | SolidWorks Student Design Contest |

| 112 | 64- and 32-bit version of ThinkDesing 2012.1 |

| 114 | COSCOM ProfiCAM – new functions and improved operation for a higher productivity |

| 115 | Slovenian inventors at HP Horizont 2012 |

| 120 | Eplan expands the product portfolio with software for cable harness design

|

Pulse Abroad

| |

| 122 | Simultaneous positioning and clamping

|

| 124 | FANUC service increases availability and efficiency of machines Today, FANUC is the leading global manufacturer of factory automation, with more than 2.4 million CNCs and 250,000 industrial robots installed worldwide. FANUC employs 6500 people in all corners of the globe. One third of the staff at the headquarters in Japan are young and innovative engineers in research and development.  |

| 126 | New findings and applications of pulse-plasmanitriding for gear and drive technology |

| 130 | The new C 400 basic machining centre – new, strong, and precise

|

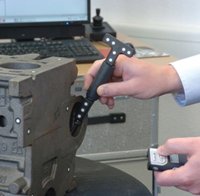

| 132 | Hand-held Touch Probe GOM ATOS is an optical 3D surface measurement system, for the first time ever combined with a tactile coordinate measuring touch probe.  |

| 133 | Jewellery and light at EuroMold |

| 134 | Trieste Next – European forum of innovation and scientific research |

| 135 | SECO announces new members of the Threadmaster family |

| 136 | Long life contact MIG/MAG welding nozzle |

| 138 | Cure for the clouds |

| 141 | 19. EuroMold brings special thematic units |

| 144 | Walter roadshow |

| 146 | Demanding high-speed machining |

| 152 | Total process control with optical 3D digitizing |

| 153 | SMW AUTOBLOK 6-jaw sequence chuck for automated machining of pipes |

| 154 | Vienna-Tec industrial fair |

| 156 | AMB 2012 international exhibition for metal working in Stuttgart

|

List of advertisers in 41. number of IRT3000

List of advertisers in 41. number of IRT3000

| 3BM d.o.o. 3WAY- Tomaž Vujasinovič s.p. ABB d.o.o. ACAM, d.o.o. Alfleth Engineering, d.o.o. ANNI, d.o.o. ARBURG GmbH Beckhoff Avtomatizacija d.o.o. BÖHLER Slovenija BTS Company, d.o.o. CAJHEN d.o.o. Camincam, d.o.o. Celjski sejem d.d. DATA COM, d.o.o. EGES revija ENGEL EUROMOLD sejem FANUC Robotics Czech s.r.o. FESTO, d.o.o. FS - VENTIL revija FUCHS Maziva LSL d.o.o. HALDER, d.o.o. Hasco Austria Ges.m.b.H. Hella Saturnus Slovenija, d.o.o. HIDEX, d.o.o. Ib-CADdy, d.o.o. Ib-procadd, d.o.o. 89 IFAM sejem 57 Ing. Punzenberger COPA-DATA GmbH ITS, d.o.o. KMS d.o.o. | LCR d.o.o. |