Meusburger is setting new standards in process reliability and supply security

15.03.2024

Meusburger, renowned for its high-quality standard parts manufacturing, promises unparalleled quality and reliability with its extensive selection of plates. Operating from a vast warehouse in Austria, the company ensures process reliability and supply security through its in-house production and advanced quality control measures

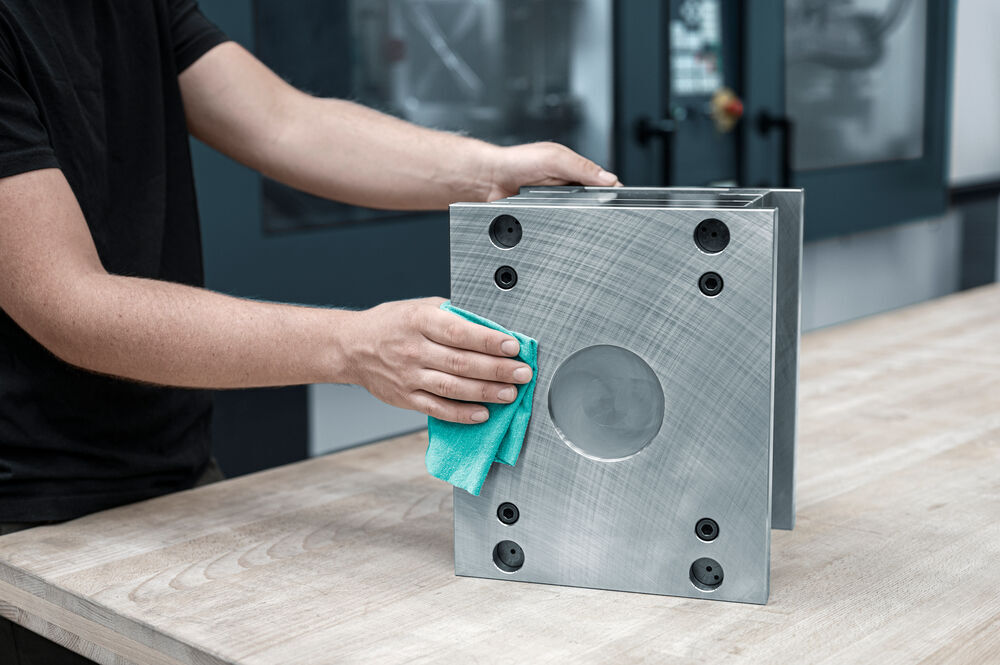

Thanks to the high level of in-house production, Meusburger is able to manufacture top-quality plates. (Source: Meusburger)

Thanks to the high level of in-house production, Meusburger is able to manufacture top-quality plates. (Source: Meusburger)

Meusburger, a leading manufacturer of standard parts, offers an extensive selection of high-quality plates across more than 30 material grades, covering an area equivalent to 2.5 football fields. With a significant portion of its production carried out in-house, the company ensures top-notch quality, process reliability, and supply security for its customers.

The company places a high priority on quality, producing all plates entirely within its facilities in Austria. Utilizing highly automated production lines and well-trained staff, the manufacturer achieves precision in the micro (μ) range.

To attain the highest quality, Meusburger subjects its sheet metal to spectral analysis and strength testing before undergoing stress-relief heat treatment in their own furnaces. This process not only improves the material's condition for minimal-deformation processing but also reduces the risk of sudden tool failures and the need for large machining allowances, thereby saving time and extending mould service life.

Meusburger's headquarters in Austria houses the largest central warehouse for standard parts, allowing for immediate dispatch of most standard plates. This, combined with excellent ordering and delivery services, facilitates seamless project implementation for customers.

With 60 years of experience in steel processing and offering over 110 different mould sizes, Meusburger stands as a dependable partner in mould making. The product range includes:

- Mould sizes: 96 x 96 to 996 x 1,196 mm

- Drilled and non-drilled plates

- Introduction of a cooling hole between guiding hole and screw connection possible

- Cavity plates with lever slots and alignment edge for an easy removal and fast alignment

- Wide and narrow versions of the ejector set (from mould size 196 x 196 mm) with matching risers

- Risers F 70 with thread for removal of the clamp plate together with the risers

Source: Meusburger

Link to the original article:

https://www.etmm-online.com/meusburger-is-setting-new-standards-in-process-reliability-and-supply-security-a-9d7adac7ce5cd005d482383cc197d360/?cmp=nl-229&uuid=8ab0749c5b6b5ad2b3571e87a3df2790